-

Welcome to Stafford Forum. Please or sign-up and start posting!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Screws...

- Thread starter basil

- Start date

Gramaisc

Forum O. G.

You just need a good, long screw, driven home hard.

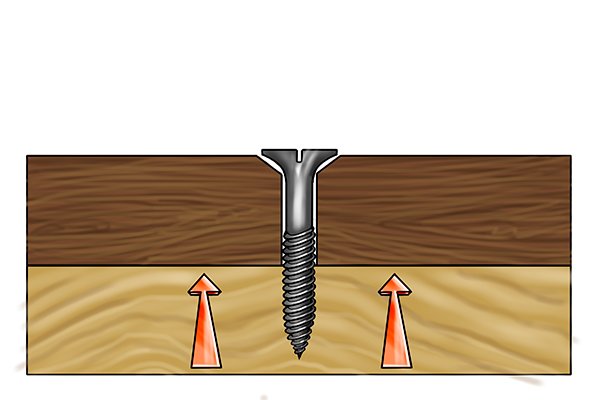

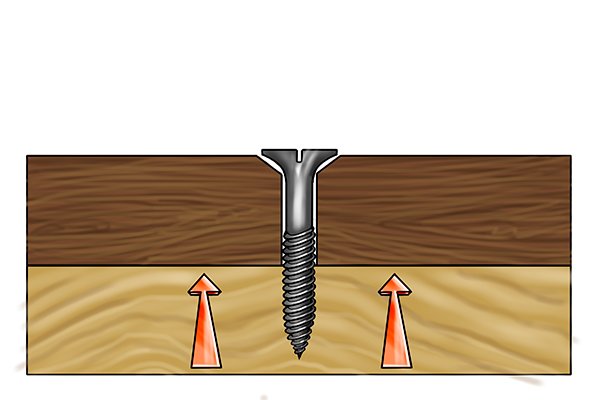

Decking screws would be OK. Ideally, it should be longish (not long enough to come out the other side of the beam, of course) and with a plain section that is longer than the thickness of the boards. In most substances, the head will pull in below the surface.

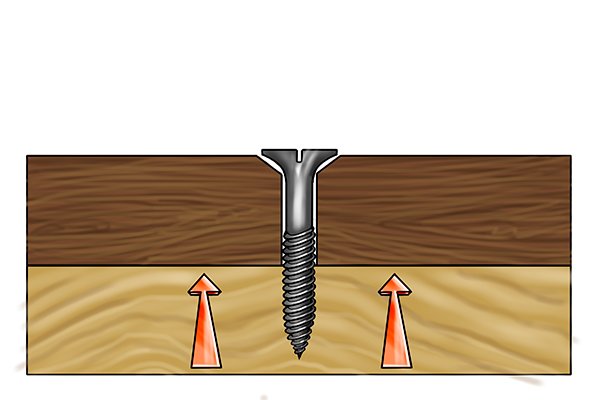

Avoid fully threaded screws, like this.

You can end up back where you started, especially in chipboard. The thread can just hold the faces apart, then, after the floor has been walked on a few times, you can be back to squeaking on the original nails, if that is what is happening.

Nailing chipboard floors is not a good idea,.

Decking screws would be OK. Ideally, it should be longish (not long enough to come out the other side of the beam, of course) and with a plain section that is longer than the thickness of the boards. In most substances, the head will pull in below the surface.

Avoid fully threaded screws, like this.

You can end up back where you started, especially in chipboard. The thread can just hold the faces apart, then, after the floor has been walked on a few times, you can be back to squeaking on the original nails, if that is what is happening.

Nailing chipboard floors is not a good idea,.

John Marwood

I ♥ cryptic crosswords

Snow shoes

Distributes the weight more evenly

Fetching too

Distributes the weight more evenly

Fetching too

Withnail

Well-Known Forumite

Apricot

Well-Known Forumite

You just need a good, long screw, driven home hard.

Decking screws would be OK. Ideally, it should be longish (not long enough to come out the other side of the beam, of course) and with a plain section that is longer than the thickness of the boards. In most substances, the head will pull in below the surface.

Avoid fully threaded screws, like this.

You can end up back where you started, especially in chipboard. The thread can just hold the faces apart, then, after the floor has been walked on a few times, you can be back to squeaking on the original nails, if that is what is happening.

Nailing chipboard floors is not a good idea,.

That explains a lot! If only I'd known about not using fully threaded screws when I was building the shelving for the back of my van.

This sort of stuff should be taught at school.

Gramaisc

Forum O. G.

If it's feasible, you could pop the screws out, one at a time, drill a clearance in the shelf and bang 'em back in again.That explains a lot! If only I'd known about not using fully threaded screws when I was building the shelving for the back of my van.

This sort of stuff should be taught at school.

If the shelves are actual wood ( or plywood ) the screw may tighten in the shelf, without really pulling the shelf hard against the beam (or whatever) the shelf is intended to be attached to.

Edit - that should really say "drill a clearance hole in the piece that has the head-end of the screw in it", just in case the screws are fitted though the beam ( or whatever ) into the shelf.

Woodwork teachers are required by law to be called Mr Williams.This sort of stuff should be taught at school.

Last edited:

John Marwood

I ♥ cryptic crosswords

If it's feasible, you could pop the screws out, one at a time, drill a clearance in the shelf and bang 'em back in again.

If the shelves are actual wood ( or plywood ) the screw may tighten in the shelf, without really pulling the shelf hard against the beam (or whatever) the shelf is intended to be attached to.

Edit - that should really say "drill a clearance hole in the piece that has the head-end of the screw in it", just in case the screws are fitted though the beam ( or whatever ) into the shelf.

Woodwork teachers are required by law to be called Mr Williams.

Nasher Harris ( author )

Taught in Stafford

[url=https://postimg.org/image/s6uja4cpr/]

gifs upload[/URL]

gifs upload[/URL]

Last edited:

Apricot

Well-Known Forumite

If it's feasible, you could pop the screws out, one at a time, drill a clearance in the shelf and bang 'em back in again.

If the shelves are actual wood ( or plywood ) the screw may tighten in the shelf, without really pulling the shelf hard against the beam (or whatever) the shelf is intended to be attached to.

Edit - that should really say "drill a clearance hole in the piece that has the head-end of the screw in it", just in case the screws are fitted though the beam ( or whatever ) into the shelf.

Woodwork teachers are required by law to be called Mr Williams.

I got a reasonable result in the end. I built the shelves first using metal brackets to hold them together, so all that was fine, it was just when I tried screwing the shelf units into the van's plywood lining that I had problems. But in the end I got them lying flat against each other, not quite sure how, I just remember repeatedly screwing them, which may have had the effect of making the hole through the shelf larger, as in your diagram.

It's obvious now you explain it.

I went to an all-girls school which is probably why they didn't have woodwork. And to be fair, if they had taught it then, I would have forgotten it by now. But I seem to spend a lot of my adult life trying to get to grips with basic woodwork / diy / plumbing / car maintenance / vegetable growing stuff that I feel I ought to know.

I can wire a plug, but only if I refer to that bit of card that used to come with them, that tells you which wire is which.

Gramaisc

Forum O. G.

Surely you could have sewed them on?I went to an all-girls school which is probably why they didn't have woodwork.

Actually, I never did woodwork at school at all. A bit of metalwork, but not much of any real use. I learnt most of mine up the Tip after school.

Glam

Mad Cat Woman

I can wire a plug, but only if I refer to that bit of card that used to come with them, that tells you which wire is which.

Please don't start all that up again!! x

Apricot

Well-Known Forumite

Surely you could have sewed them on?

Actually, I never did woodwork at school at all. A bit of metalwork, but not much of any real use. I learnt most of mine up the Tip after school.

I did mend my car seat by darning it.

Gramaisc

Forum O. G.

We don't want that going live again, after we've finally managed to get back to a neutral situation. Let's just run it to earth and leave it.Please don't start all that up again!! x

Sewing (neatly) has never been my thing.I did mend my car seat by darning it.

Thehooperman

Well-Known Forumite

We don't want that going live again, after we've finally managed to get back to a neutral situation. Let's just run it to earth and leave it.

Gramaisc - you're grounded!!!!

Gramaisc

Forum O. G.

I expected repercussions, but I'm shocked that it's you that decided to socket to me.Gramaisc - you're grounded!!!!

Thehooperman

Well-Known Forumite

I expected repercussions, but I'm shocked that it's you that decided to socket to me.

Darn you