Gramaisc

Forum O. G.

Chilly out again today, so, apart from the bike ride, it's just been little jobs in the Shed.

I broke the spring on one of these secateurs ages ago and just spotted what looked like a very similar one in a pump bottle that was going into the recycling.

Almost a perfect replacement.

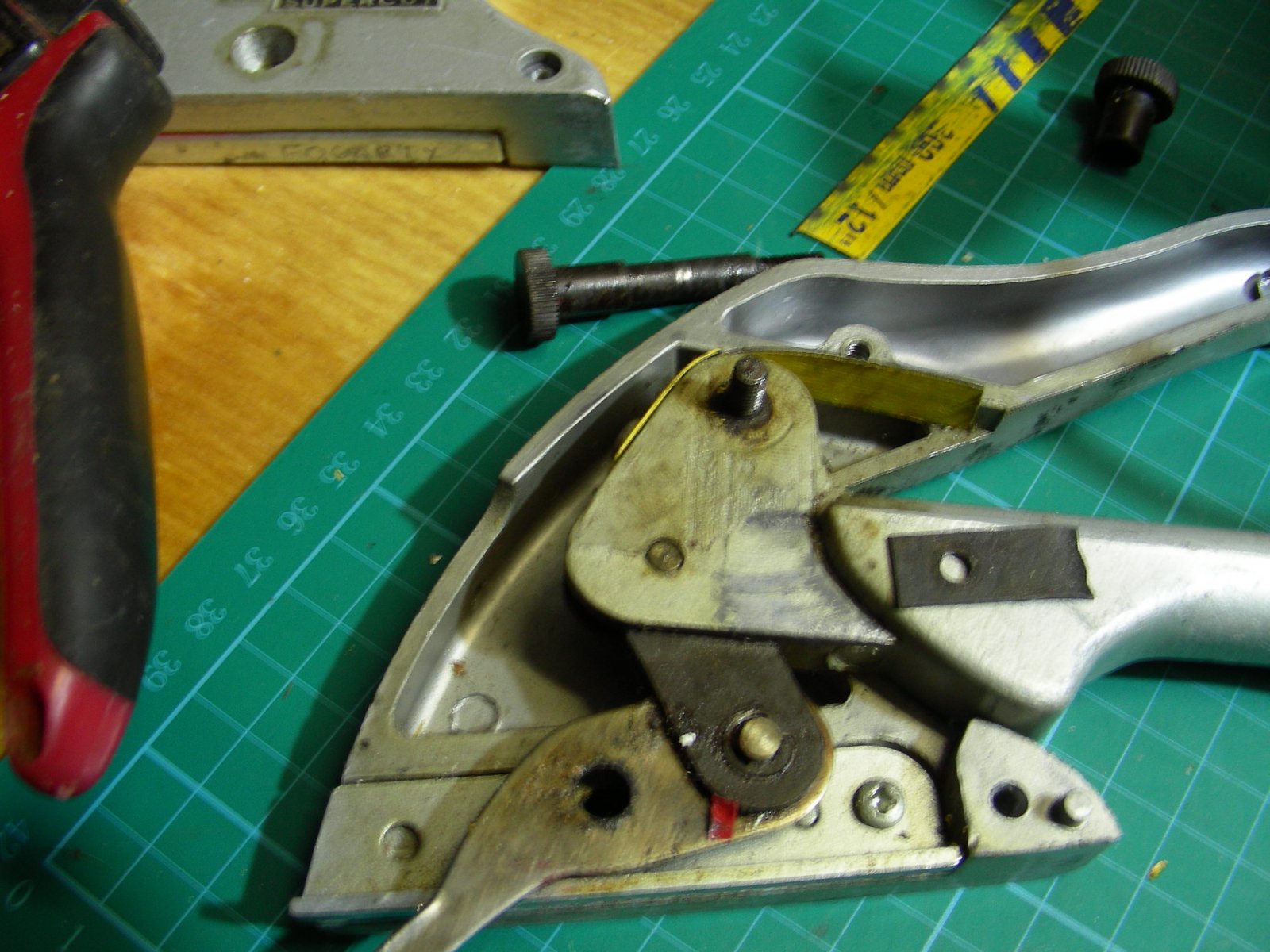

Also, the metal shears in the background above also had a broken spring, a leaf spring this time - you can see the remains on the handle. This was replaced with a piece from the end of a broken hacksaw blade - it even had a suitable hole in it.

It's very awkward to use without the spring, so my trusty Mole Supercut is back in action again - we'll see how long the 'new spring' lasts...

I broke the spring on one of these secateurs ages ago and just spotted what looked like a very similar one in a pump bottle that was going into the recycling.

Almost a perfect replacement.

Also, the metal shears in the background above also had a broken spring, a leaf spring this time - you can see the remains on the handle. This was replaced with a piece from the end of a broken hacksaw blade - it even had a suitable hole in it.

It's very awkward to use without the spring, so my trusty Mole Supercut is back in action again - we'll see how long the 'new spring' lasts...

For now it's mostly decorative because I have to figure out how to get an aerial to it. The other side of that wall is the garage, which suggests going directly through it for a feeder. It's in the planning stage.

For now it's mostly decorative because I have to figure out how to get an aerial to it. The other side of that wall is the garage, which suggests going directly through it for a feeder. It's in the planning stage.